Our Quality Mantra

Our quality policy “Make it Right The First Time”, is an enabler for our team to upgrade their workmanship continuously and deliver products with zero defect adding value to our customers.

Quality Assurance & Control

To meet our quality mantra, we employ a robust quality program

1. Incoming Material Quality Control

We use best quality raw material for manufacturing by entering into long-term supply chain agreements with the world’s top suppliers. Incoming materials undergo stringent quality checks in our dedicated QC laboratories. The materials are also sent to third party testing centers on periodic basis to reassure our tests are calibrated to top industry practices.

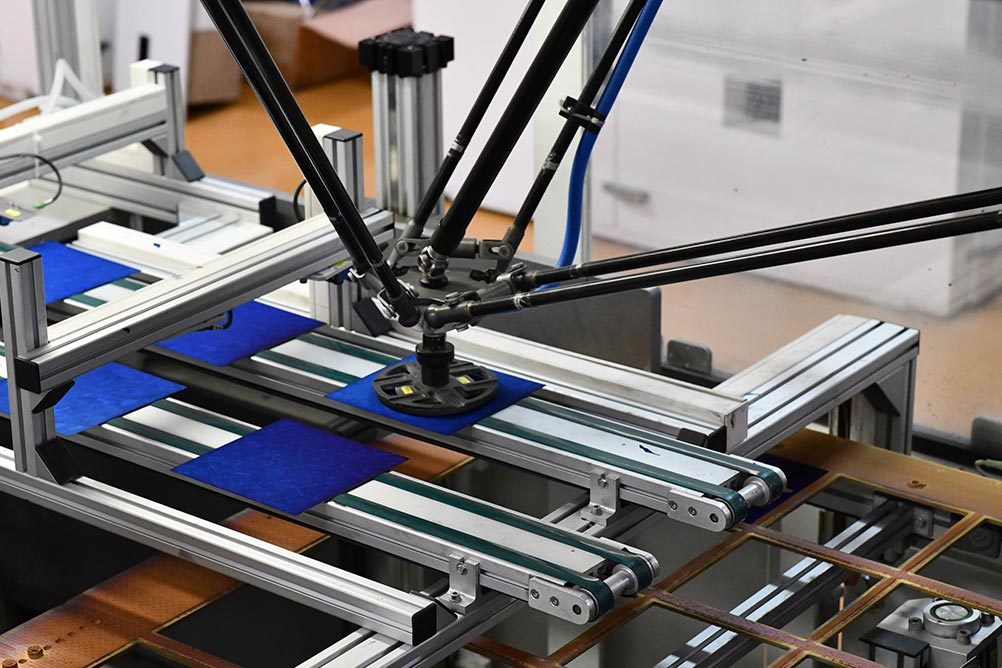

2. In line Process Quality Controls

The cells and panels undergo 100% In-line Inspection. Our machinery is equipped to measure the production control parameters at every stage enabling us to maintain checks throughout the process.

3. Post Production QA

Our QA team is provided with latest testing equipments, positioning us ahead of quality standards employed worldwide.

4. Testing, EL Measurement & Sorting

100% of our cells and modules are tested and sorted to ensure that only QA approved cells and panels are dispatched from our works. The cells are tested under real-time conditions by creating environmental conditions in testers calibrated with internationally known standards and equipped with AAA flash light sun simulators.

The important metrics of the cells and panels are recorded in the form of IV characteristics. Stringent monitoring of the following metrics play an important role in the durability and performance of PV cells and modules :

1. Short circuit current (Isc)

2. Open circuit voltage (Voc)

3. Maximum Power Point Current (Imp)

4. Maximum Power Point Voltage (Vmp)

5. Power at maximal power point (Pmax)

6. Fill factor (FF)

7. Reverse Current measurements at -10V & -12V (Irev)

The cells are electrically and optically sorted through automation for metallization pattern and color classification in different classes bringing high-aesthetic value and visual characteristics to our cells and panels.

Inline Measurement Equipment

Life Time and Sheet Resistance are measured at 100 % cell with in- line measurement equipment.

In house reliability tests:

Cells undergo routinely for water boil, solder-ability and peel- off tests. Modules are tested on EL tester for identifying any major discrepancy or hot spots.