Module Manufacturing

Module Manufacturing

Our modules are designed to the highest standards of quality, reliability and performance.

Our integrated manufacturing of cells and modules have been an imminent combination.

Our modules carry Industry leading 25-year power output warranty.

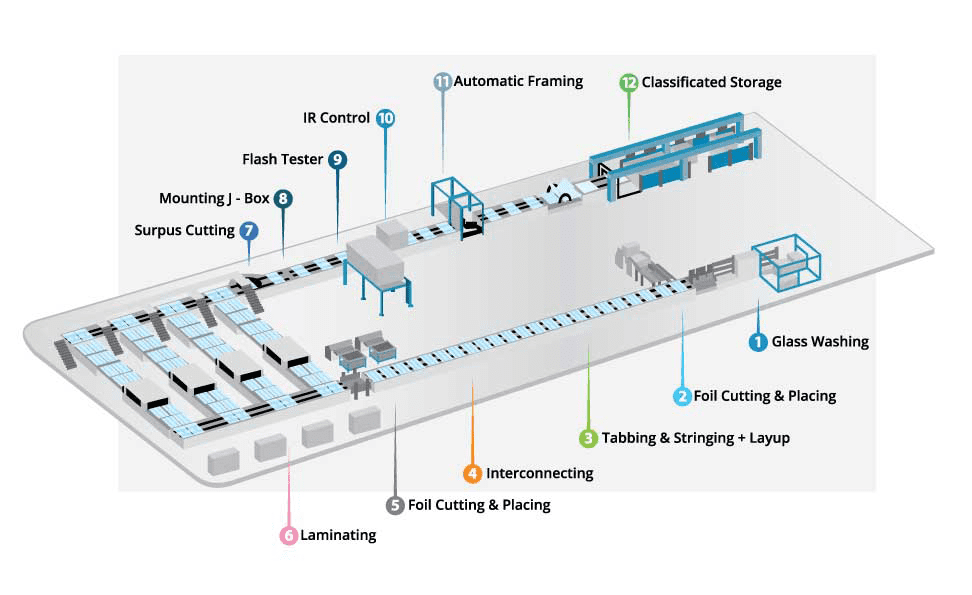

Fully Robotic Vertically Integrated Plant

Module Manufacturing Process

Cell Tester

Here the cells are tested on different parameters like open circuit voltage, Short circuit current and Maximum power point curent and voltage respectively.

Electroluminescence Tester

This machine is able to detect micro-cracks/ degradation and shunt areas on the cell.

Sun Simulator

Is a device that provides natural sunlight. The machine is used for testing solar cells, sunscreen, plastic and other materials and devices under lab conditions.

Laser Cell Cutter

A laser cutter machine is used to cut cells according to the size of the module being produced.

PV Laminator

It is used to join all the layers forming the module, ensuring immunity to the cell against dust, moisture, humidity, and other environmental conditions.

Tabber & Stringer

This machine assembles and welds the photovoltaic cells together. Tabber connects ribbon on cells whereas the stringer connects one cell to another.

Framing & Sealing

The modules are finished with an aluminium frame around the edge. The frame increases mechanical strength, which makes it easier at the time of installation.